Industrial fiber and film are the origins of modern sailcloth. Today, some of these products are well recognized by sailors. But despite brand names, the material quality of these products are not always well understood. Thus, understanding the properties of these fibers can assist you in the ultimate defense sails selection. Now, the ideal sailcloth material would be long-lasting. It must be able to withstand severe sailing environments, for instance. In addition, the material must exhibit qualities like toughness, structural durability, elasticity, and economic.

However, accessible fibers have varying degrees of these characteristics in the actual world. Some materials even have small amounts of flexibility for weight, less-than-desirable durability, and lack of elasticity.

At this point, let’s start with the numerous fibers included in high-quality sailcloth. From there, go on to some of the more unusual products that have developed through time.

Sailcloth Polyester (Dacron)

Dacron is the most widely used sailcloth. This fabric is a long-lasting and tightly woven polyester. For decades, such use of material has been used successfully in practically all settings. Even though it isn’t the most durable sailcloth, it is inexpensive and long-lasting. It also requires little maintenance. As a result, this makes it a suitable substitute for older organic sailcloth. In comparison, Dacron sails last for years when properly cared for. Subsequently, you can count for the material to require very little maintenance. They’re also simple to fix, and almost every sailmaker has enough Dacron on hand to build custom sails.

Ideally suited to sailcloth over the years, other suppliers have introduced superior polyester yarns. Polyester has high shrinkage combined with extremely fast weaving resulting in a densely packed and durable sailcloth without additional and less durable resins. A fabric utilized as a standalone woven cloth and a laminate component are Polyester. One could even expect its UV resistant feature to also be a great add on.

Pros:

- Durable

- Common to use

- Lightweight

- Highly affordable

- Resistant to bilge rot

- Suitable for almost all applications

- Easy to repair, maintain, and create

Cons:

- Less durable than other types

- Stretches more than any premium sailcloth

Carbon Fiber Sailcloth

Carbon fiber is distinguished by its high strength-to-weight ratio and is believed to be the most promising new sail material today. This exceptionally durable and lightweight material is used extensively in racing boats. Carbon fiber can be utilized in sail making and produce a rigid shell-like hull. It doesn’t stretch or degrade quickly, and it’s been proven in various applications. For instance, carbon fiber sails are frequently the most expensive due to the material’s high cost of manufacture and processing.

Carbon fibers are UV resistant and have a high modulus, yet they are quite sensitive. When you fold a raw carbon fiber strand in your fingers, it snaps after only one or two hard folds. Also keep in mind that when flaking or folding a sail, crews must be very careful to avoid flogging and hard wrinkles, depending on the carbon content and construction of the sailcloth. A major advance in the use of carbon is its combination with Ultra PE fiber, where the complementing qualities of the two materials are synergistic.

Pros:

- Lightweight

- Stiff and non-stretching

- Used and trusted by racing teams

- Extremely strong

Cons:

- Demanding to repair

- Challenging to manufacture

- Expensive for normal sailors

Laminated Sailcloth

The first thing to remember is that laminated sailcloth occasionally emerges from the laboratories of petrochemical companies. But, it is frequently of limited utility for sailcloth applications. Alternative to Dacron, a laminated Sailcloth has a high quality. Multiple components and layers of material make up laminated sails. The components are frequently varied, and the material combinations differ depending on the intended function.

North’s approach to novel fibers is then to study laboratory performance numbers thoroughly. To enumerate their process: find a likely appropriate usage for the fiber, create the right fabric design, and select the appropriate sail size range before proceeding. Finally, any new fiber must undergo comprehensive testing to ensure that it lives up to its promises. Some laminated sails are designed to be lightweight, while others are designed to be strong, stretch resistant, and long-lasting.

Pros:

- Efficient

- Weather-resistant

- Durable

- Highly stretch-resistant

- Known for its numerous material combinations

Cons:

- May decay faster during storage

- Much expensive than non-laminated alternatives

Hemp Fabric Sailcloth

To make hemp fabric or textile, you need Cannabis Sativa Fiber or Industrial hemp. The use of hemp fiber as a garment material is not a new concept. Early civilizations in Asia, the Middle East, and China employed hemp for various purposes. In Asia and the Middle East, hemp was used to make paper, rope, ships’ rigging, canvas, sailcloth, sacks, and many other things.

Hemp is the most durable, strong, and long-lasting natural textile fiber. Hemp-based products will outlast their counterparts for many years. Hemp is robust, but it also maintains its shape better than any other natural fabric, including cotton. Furthermore, it will not stretch out or become deformed. Known for its strength, comfort, and style, Hemp is unrivaled. The more you use it, the softer it becomes. It is also inherently anti-microbial and odor-resistant since they kill bacteria. Hemp fiber clothing is thermoregulating, meaning it keeps the boat cool in the summer and warm in the winter.

Pros:

- Robust

- Environmentally friendly

- Easy to repair anywhere in the world

- Traditional choice

Cons:

- Heavy

- Vulnerable to water and natural decay

- Easily waterlogged

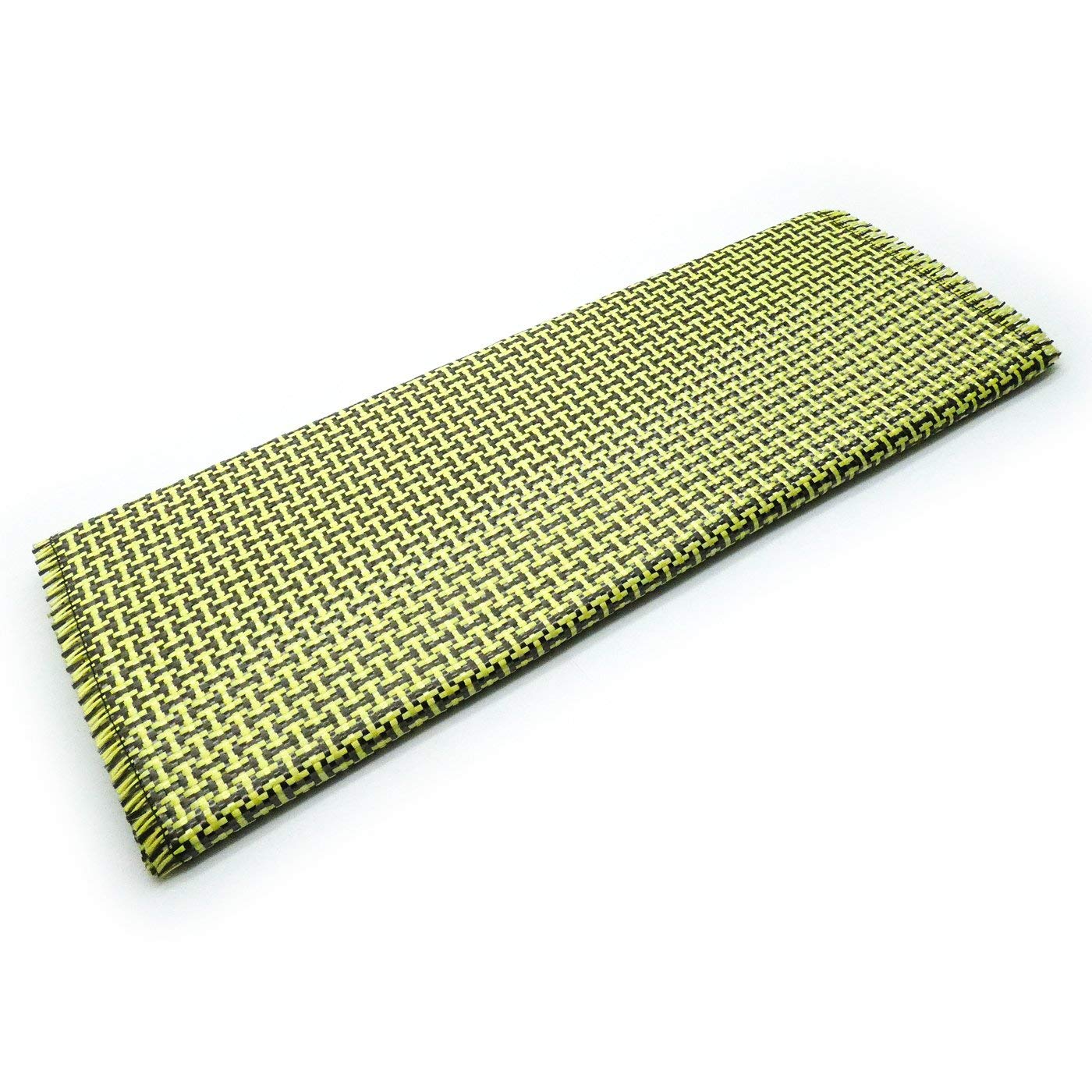

Aramid Fiber

Aramid fiber was the first organic fiber with a high tensile modulus and strength as reinforcement in advanced composites. They outperform steel and glass fibers in mechanical qualities on an equal weight basis. Aramid fibers are heat and flame-resistant by nature, and they retain these qualities at high temperatures. Within the same racing sail, even lower-stretch and higher-stretch carbon, Aramid fibers combined them both. Aramid Fibers are pricy.

Heat resistance, low flammability, and excellent resistance to organic solvents are all advantages of aramid fibers. In to the presence of hydrogen bonding, aramid fibers are polar. This characteristic improves aramid fibers’ wettability and makes them more chemically active than UHMWPE fibers. Aramid fibers have a low resistance to UV light by nature. As a result, when exposed to ultraviolet radiation, fabrics comprised of aramid fibers change color.

Pros:

- Good resistance to scrape and cut

- Good fabric integrity at elevated temperatures

- High strength to weight properties

- High tenacity

- Chemically resistant to organic solvents

Cons:

- Sensitive to acids, bases, and chlorine

- Sensitive on exposure to UV radiation

Final Takeaway

There are so many possibilities on the market today. And picking the ultimate defense sailcloth is one of those and is rather difficult. So in order to avoid this, the first thing to think about is what your boat came with. Polyester was used in most fiberglass sailboats, and it is still acceptable for most applications. However, if you plan on racing or undertaking a lengthy offshore journey, you should think about various sailcloth fabrics.